Hankook Tire is furthering its commitment to enhance the sustainability across its value chain for natural rubber, a primary raw material for tyres.

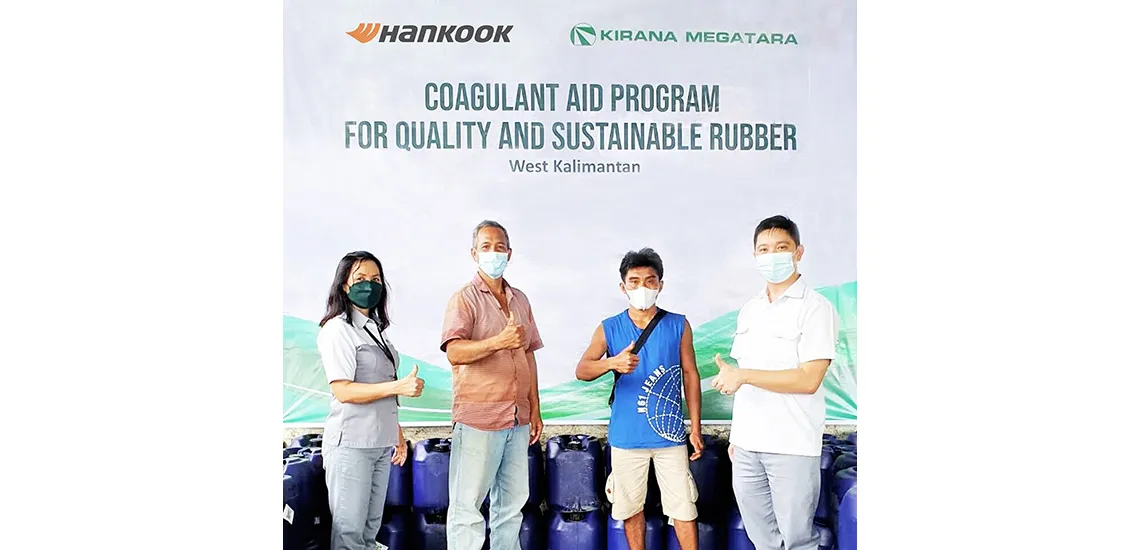

Hankook Supplies Formic Acid to Rubber Farmers in Indonesia

The production of tyres accounts for about 70 per cent of global natural rubber consumption, and approximately 85 per cent of global rubber production relies on smallholders in Southeast Asia. The production of natural rubber begins with a small rubber lump, created through coagulation of natural rubber latex collected by the farmers. Various types of coagulants are used for rubber lu...

Hankook Supplies Formic Acid to Rubber Farmers in Indonesia

The production of tyres accounts for about 70 per cent of global natural rubber consumption, and approximately 85 per cent of global rubber production relies on smallholders in Southeast Asia. The production of natural rubber begins with a small rubber lump, created through coagulation of natural rubber latex collected by the farmers. Various types of coagulants are used for rubber lu...