Yokohama Rubber has developed a highly crack-resistant rubber material made from nanoparticle-based polymers that can be recycled without deterioration.

Yokohama Uses Nanoparticle Technology to Develop Crack Resistance Rubber Material

This highly crack-resistant rubber material, according to Yokohama do not use any additives, such as organic solvents and reinforcing agents.

The development is the result of a collaborative effort with a research group led by Associate Professor Daisuke Suzuki of Shinshu University’s Graduate School of Textile Science and Technology and RISM (Research Initiative for Supra-Materials). Further research based on knowledge gained during the collaborative research project is expected to lead to the development of safer and more durable tyres and rubber products that are people- and environment-friendly. The developed rubber material can be easily recycled without deterioration and therefore is expected to contribute to the realisation of a circular economy.

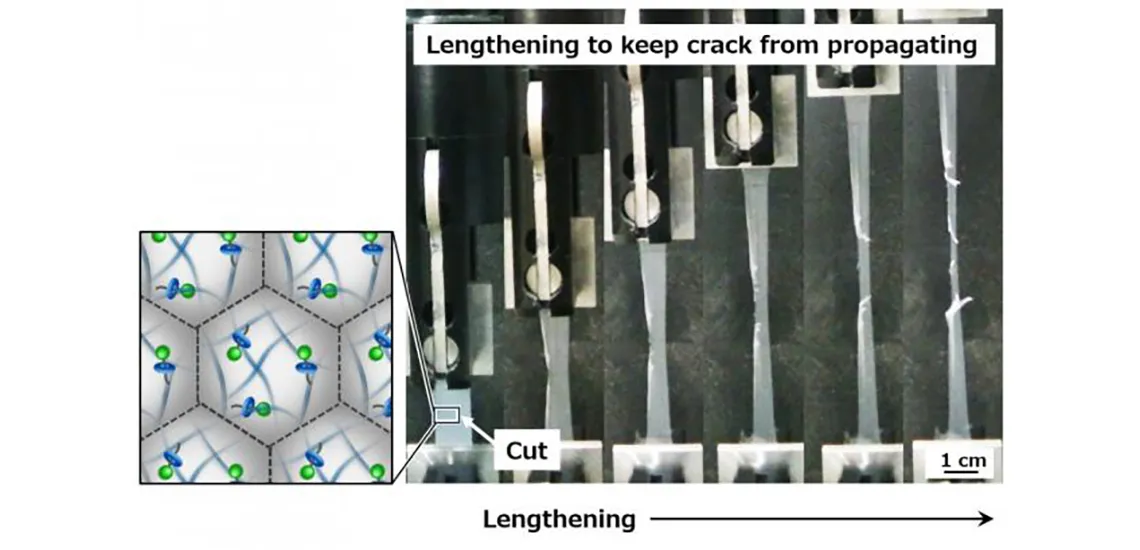

The research project used nanoparticle-based polymers (hereafter, “nanoparticles”) synthesized via mini-emulsion polymerisation, a well-known polymerisation method, and a nanoparticle dispersed aqueous solution to create a nanoparticle film (rubber material) formed by evaporating the water from the dispersed aqueous solution. Inserting rotaxane molecules, also known as supramolecular compounds, into these nanoparticles as a crosslinking agent enhances their resistance to crack propagation without using other additives, such as reinforcing agents. This nanoparticle film also contributes to the rubber material’s high elasticity.

In addition, nanoparticle films composed of nanoparticles only can be decomposed simply by immersing them in a water-ethanol solution, namely a low environmental-impact process. Since this water-ethanol solution can be returned to the dispersed aqueous solution that is composed of nanoparticles and water simply by evaporating the highly volatile ethanol, the nanoparticle film can be easily regenerated without any deterioration.

The research results were published in Langmuir, an American Chemical Society journal, on 17th June.